The infrastructure at Adak Metcast Engineers Private Limited plays an important role in enabling us to meet the exact requirements and standards of the industry. We are empowered by a modern infrastructure and supported by highly experienced professionals. All our equipment and machinery incorporate the latest technologies that enable us to maintain our competitive edge in the market. We believe on updating the clients and users on various developments of the product and its applications. The company continuously organizes seminars and workshops to update on various subjects at frequent intervals. Also training programs on installation techniques are organized for benefit of users for best installation and maintenance practices.

A quick look at our Infrastructure

♦ Melting capacity of over 20,000+ MTPA.

♦ 1 no. 1 ton double track Electrotherm furnace; 1 no. 500 kg Inductotherm make induction melting furnace.

♦ Material: Grey/Ductile iron (CG 20/25 for Grey Iron and GGG for Ductile iron).

♦ DISA make arpa-900 moulding machine.

♦ DISA make arpa-450 moulding machine.

♦ DISA make arpa-300 moulding machine.

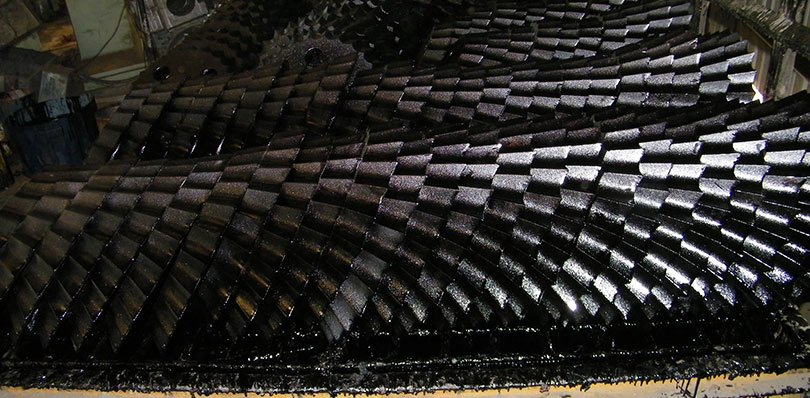

♦ No bake moulding line one 5 tons continuous sand mixture for core making.

♦ Fully automated reclamation sand plant system.

♦ Handling and punch out system and mould manipulator.

♦ DISA make automatic sand plant with Mixture Machine (500 kg per 105 seconds capacity), Mechanized Sand Plants with Separate Sand for Machine and Hand Moulding. All systems are panel controlled.

♦ Integrated cooling conveyors, Shakeouts and Shot Blasting facilities.

♦ 2 nos. Shot Blasting machines, make DISA, with Dust Extraction System.

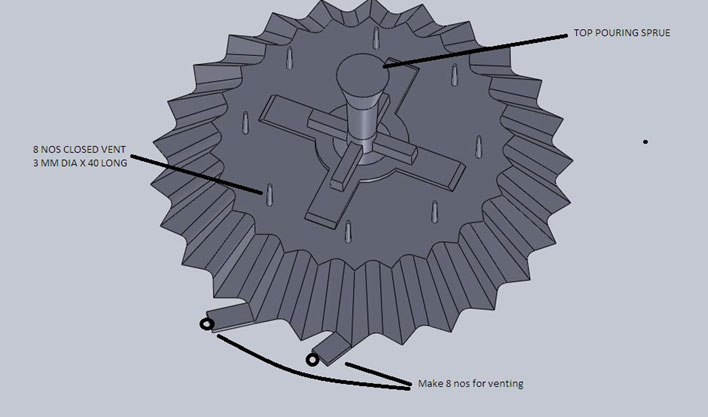

♦ Multiple CNC and 4 Axis VMC Machines for developing new patterns.

♦ Creo®, Solidworks® and Declam® for design and optimization.

♦ Complete machine solutions.

♦ Integrated Paint-Shop for Spray Painting.

♦ Black Bitumen, Water Based, Epoxy and Primer Painting facility also available.

♦ Fully equiped chemical, physical, paint and sand laboratories.

♦ In-house testing of product qualities.

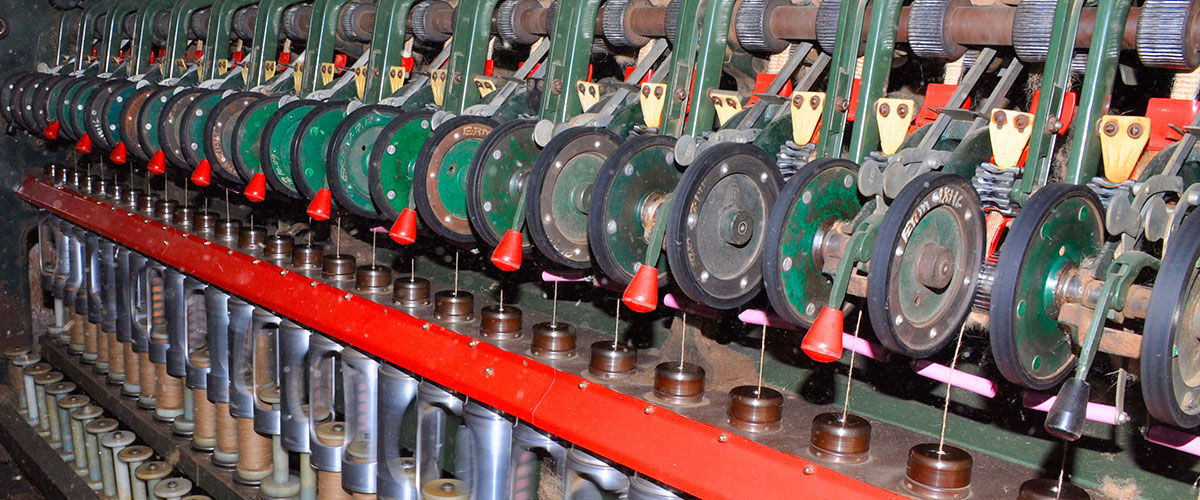

1 Automatic Sand Preparation Plant

♦ DISA make automatic sand plant with Mixer Machine (500 Kg per 105 sec capacity), Sand distribution system to every machine point hopper by belt Conveyer, All system are panel controlled

♦ Main Sand Hopper with a capacity of 40 Ton sand

♦ Polyglonal Screen Type Ts-5, 40 M3 / hr

♦ Over Band Magnetic Separator -650

♦ Bucket Elevator 40 M3 / hr

♦ Batch Hopper – 500 Kg

♦ Surge Hopper 500 Kg

♦ Belt Conveyor 650mm, Speed 1 mtr / sec

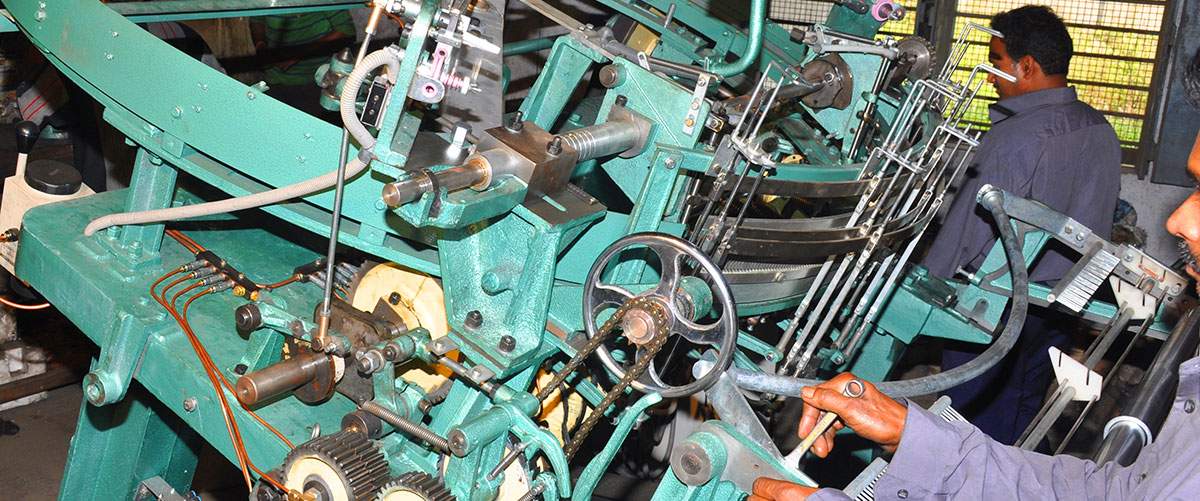

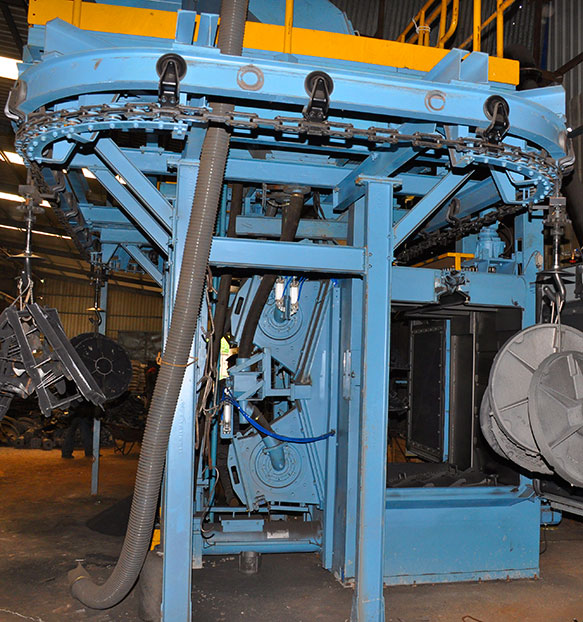

2 Mould Making and Mould Handling

♦ DISA make Arpa-900 Moulding Machine – 1 set

♦ DISA make Arpa-450 Moulding Machine – 1 set

♦ DISA make Arpa-300 Moulding Machine – 1 set

♦ Pallet Car 900 mm X 600 mm: 72 Nos

♦ Pallet Car 1100 Mm X 1450 Mm: 56 Nos

♦ Transfer Car 7 Nos

♦ Track for Pallet / Transfer Car

♦ Hydraulic Push and Brake Cylinder

♦ Hydraulic Power Pack

3 No bake molding line

♦ One 5 tonnes Continuous Sand Mixture from JKFE For core making

♦ Fully automated reclamation sand plant system

♦ Handling and punch out system and mould manipulator

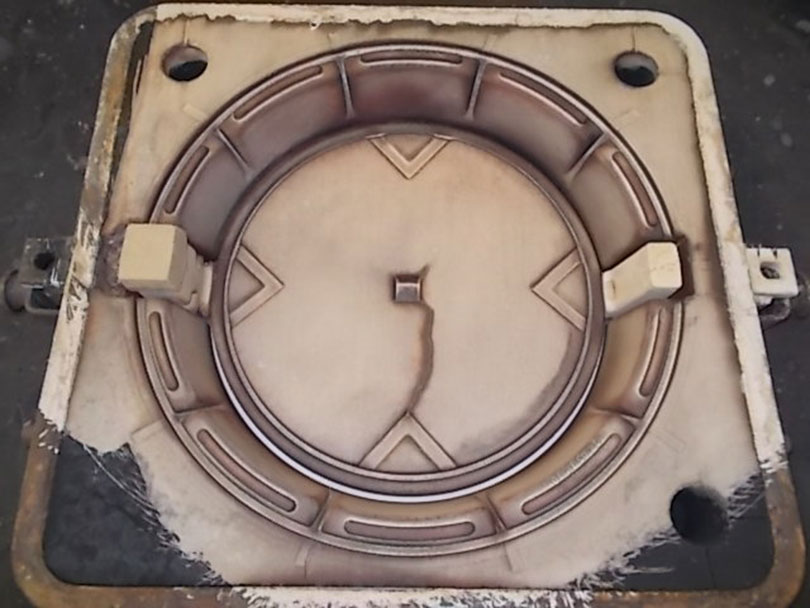

4 CO2 Mold and Core Preparation

♦ Core sand mixer and Carbon Dioxide core making facility

♦ Cold Box core shooter from Kelson machines vertically parted box size 600 mm X 500 mm

♦ Automated sand system including sand mixture and dosing system to support the above Core machines

5 Melting

500 Kg INDUCTOTHERM Make Induction Melting Furnace.

Power Unit : 500 KW / 500HZ R-PI Power and Control System with Internal Water Circulating System,

♦ Tea spout Ladle for mould pouring in moulding line

♦ S. G. Treatment Ladle with tundish cover

♦ 5 MT Crane for Liquid Metal Handling

6 Fettling

♦ 2 Nos Shot Blasting Machine , Make – DISA, with Dust Extraction System

♦ Swing Grinder, Wheel Size – 16”

♦ Hand Grinder, Wheel Size – 8”

7 Finishing

♦ Painting - Black Bitumen or Primer

♦ Epoxy Coating

8 Finished Stockyard

9 Computerized product analysis

10 Container Stuffing Point